TECHNOLOGY

Spring FAQ

Q1

What is a “spiral spring”?

A

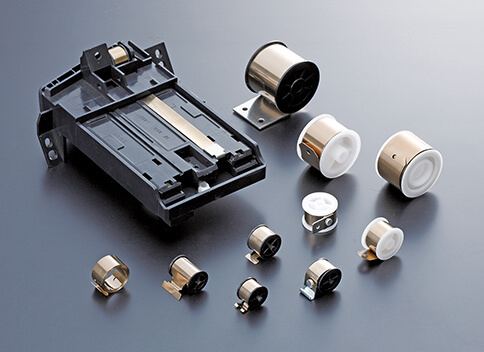

Spiral springs are the kind of springs that store rotational force (torque).

Have you ever seen these springs built-in some old wall clocks or some music boxes? They are also included in some small toys.

We manufacture spiral springs for automobile seatbelt retractors, for cord reels for winding power cords of vacuum cleaners and for the like.

Q2

What is the material being used?

A

It is said springs for “karakuri dolls” were made from whale whiskers in the past, but now the materials used are:

・SUS301-CSP EH … Stainless steel strip for spring (About t = 0.05 - 0.8)

・Carbon tool steel, such as SK95 or SK-85, quenching and tempering material.

・SK85 equivalent carbon steel, passing through patenting process before cold rolling process

・FW (Flat Wire) … Flat rolled wire rod, e.g., hard steel wire, piano wire, etc.

These are used for different purposes.

Q3

How is a spiral spring designed?

A

When designing the spiral spring, it is necessary to determine the following parameters: torque, spring stroke (revolution range), durability, case size, shaft size, and spring’s width.

Unlike non-contact springs, the torque of the spring is non-linear because part of the spring is in contact along the case or with the shaft, and it is necessary to calculate torque etc., through a numerical analysis. If you require a numerical analysis of the spring, please contact us.

Q4

How are spiral springs manufactured?

A

Cut the material to the width of the product in the longitudinal direction. (Slitting Process) The slit edge is processed by cutting / grinding or plastic working it (Rounding Edge Process).

After primary winding processing, cut to the required length of the product.

Mold the inner and outer edges.

Anneal at low temperature to increase material strength and remove residual stress. (Segmentation Process)

Perform spring winding and setting using a dedicated processing shaft (Winding Process).

Assemble the spring into the case.

Perform inspection and pack for shipping. (Inspection and Packaging Processes)

Q5

What is a constant force spring?

A

A constant force spring is made from a thin plate that is tightly wound with a constant curvature, and is used by pulling out its outer end straight. It is called a constant force spring because the force is almost constant regardless of its stroke. A spring with long stroke can be assembled in a small space.

Q6

How to design a constant force spring?

A

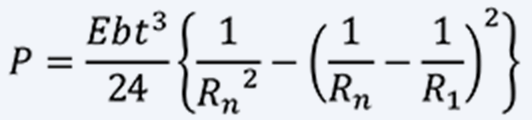

This is the basic calculation formula.

Please note that the minimum Rn is 40 times the thickness.